Liang Yanxue: The future of the 'Infrastructure Wizard' is undoubtedly construction robots

Liang Yanxue, who earned his bachelor’s and master’s degrees from the School of Mechanical Engineering at Shanghai Jiao Tong University, would surely have sung a children's song called "The Painter" during his childhood: "I am a painter, skilled in painting. I want to make that new house even more beautiful..."

Today, as the founder of WEIBUILD Technology, Liang positions his company as a "productization-leading intelligent construction firm," aiming to revolutionize the traditional construction industry. Under his leadership, a quiet but significant force of "construction robots" has emerged, specializing in tasks such as painting and plastering. In 2022, he quietly achieved a remarkable feat by deploying six "plastering robots" to assist in the construction of a new campus for the Shanghai Jiao Tong University School of Medicine. Now, he can proudly say that the plastering work at the new medical school campus was all done by robots from WEIBUILD Technology.

This achievement highlights not only the progress in construction technology but also the personal connection Liang Yanxue has with his alma mater, bringing innovative solutions back to where his journey began.

WEIBUILD plastering robot in operation during construction work.

Liang Yanxue stated to "Jiaoda New Shangyuan" that the plastering robots developed by WEIBUILD Technology have achieved an efficiency more than ten times higher than that of skilled workers.

Rewind to 2020, Liang Yanxue had just left his position as Executive Deputy Director of the Research Institute of Boticim Intelligence Technology, where he was responsible for the overall R&D of Boticim (a team exceeding one thousand people). At that time, Boticim carried the heavy responsibility of transforming Country Garden Holdings into a technology-driven company. Under Liang's leadership, the company focused on building and restaurant robot development systems, along with the research and development of nearly ten types of robot applications and foundational technologies.

Alumnus of Shanghai Jiao Tong University and CEO of WEIBUILD Technology, Liang Yanxue

Choosing which application scenario to focus on in the robotics field was a critical decision for Liang Yanxue. With the rigor characteristic of Jiaoda (Shanghai Jiao Tong University) graduates, Liang began his investigation using China's annual employment statistics. He found that the manufacturing sector employed the most people in China. However, after over a decade working on industrial robots at FANUC in Japan, Liang felt somewhat jaded toward industrial robots. In China, the construction industry followed closely behind manufacturing in terms of employment numbers, boasting a workforce of 50 million.

Liang believed that the ultimate goal of robotics is to replace human labor. The higher the labor costs and workload in a particular field, the more attention it should receive from robotics entrepreneurs. From this perspective, the construction industry needed robots even more than manufacturing did. Moreover, the global construction sector faced persistently high labor costs and worker shortages, while in China, there was a trend towards an aging workforce in construction. This trillion-dollar market offered an excellent application scenario for intelligent robots.

Deciding to go all-in on construction robots, Liang founded WEIBUILD Technology.

However, he immediately encountered the downturn in China’s real estate and construction industries. Despite this, he believed that change often arises from adversity; the challenges within the industry would force construction firms to adopt more refined management practices, making the timing right for the development of construction robots. Over four years of entrepreneurship, WEIBUILD Technology has secured multiple rounds of financing from investors such as Linear Capital, Sequoia Capital, K2VC, Poly Capital, Xiamen Jianfa, Ray Capital, Duxiu Capital, among others, and has become part of the portfolio of the alumni fund of his alma mater, Shanghai Jiao Tong University.

Liang observed that as leading general contractors begin to scale the use of robots to optimize service systems and pursue high-quality development, coupled with the gradual expansion of overseas operations by WEIBUILD Technology, the turning point for construction robots has arrived.

The Beauty of Technology and the Pain of Industry

When choosing his entrepreneurial path, Liang Yanxue opted against industrial robots because he felt they lacked challenge. After completing his bachelor's and master's degrees at Jiaoda, he went on to earn his doctorate from Tokyo Institute of Technology and then worked at FANUC in Japan as a chief researcher for over a decade. Having grown somewhat weary of industrial robots, Liang sought greater challenges.

But are the challenges posed by construction robots too great?

Liang summarized the situation as the "beauty of technology versus the pain of industry."

In the domain of industrial robots, leveraging China's comprehensive industrial system, one can establish standardized processes for implementing industrial robots by collaborating with factory managers to define tasks like material handling, welding, or assembly, analyzing task requirements and characteristics, and planning execution sequences and paths.

However, these methods do not apply in construction sites. Compared to industrial robots, construction robots operate in far more complex environments with numerous procedures and encounter significantly greater challenges.

The plastering robots manufactured by WEIBUILD Technology

The construction industry is characterized by its highly complex processes, with a multitude of procedures that have diverse and stringent requirements, making it extremely challenging to achieve full automation. Take plastering as an example; it is considered "heavy labor" in construction, requiring a long training period due to its classification as a "skilled trade." Only experienced "master craftsmen" can perform this task, which involves multiple steps such as wall measurement, setting benchmarks (gray cakes), guiding strips (strips of mortar used for alignment), plastering, scraping flat, and finishing.

Liang Yanxue has calculated that:

In the construction sector, the domestic market for plastering alone reaches 120 billion yuan.

However, plastering is also very demanding. Workers must maintain pressure on the walls to prevent issues like hollow spots, cracking, or peeling while ensuring quality and stability, all while balancing efficiency and cost. Typically, a worker can plaster no more than 50 square meters in one day, involving about 1.5 tons of mortar, indicating a very high work intensity. This results in plastering being one of the highest-paid tasks among multiple construction procedures.

Deciding to break into the general contracting segment with a plastering robot, Liang quickly realized that achieving process digitization, standardizing construction practices, and enabling group evolution for construction robots were no easy feats.

Construction is an ancient industry, and even foremen or bosses of construction companies struggle to articulate the nuances of plastering. The expertise lies in the hands of "master craftsmen," and the challenge for construction robots lies in scientifically explaining the significance of each action performed by these masters. WEIBUILD collaborated with PhDs from Tongji University to act as a bridge between master craftsmen and technicians, addressing how to digitize one of the most traditional and ancient building crafts.

Liang believes that China's past reputation as an "infrastructure wizard" was built on the hard work of laborers. However, as these "master craftsmen" age and the phrase "提桶跑路" (running away with a bucket, a metaphor for workers leaving the site) becomes popular online, there is now a need to digitize and standardize processes. Through machine deep learning, the self-evolution process can be initiated. From this perspective, the future of the "infrastructure wizard" will certainly involve construction robots.

By leveraging AI technology to learn from hundreds of skilled craftsmen and converting their experience into digital instructions, WEIBUILD achieves the digitization of construction techniques. Construction processes are then broken down into standardized steps throughout the workflow, ensuring each movement remains stable and precise, resulting in smooth, non-hollow surfaces and significantly improved efficiency and quality. Continuous backend analysis and optimization, supported by a cloud-based system, synchronize optimized algorithms to all robots, enabling collective evolution.

Currently, WEIBUILD's plastering robots surpass "master craftsmen" in safety, quality, production capacity, and delivery metrics. Liang revealed that WEIBUILD’s plastering robots can achieve up to 700 square meters per day, handle walls as high as 5.5 meters, and maintain a hollow spot repair rate of only 0.02%.

The wall surface after plastering by the WEIBUILD plastering robot.

However, an even greater challenge lies in changing the industry's mindset.

The construction industry is vast and traditional, with significant inertia due to production relationships that have been established over decades, centuries, and even millennia. The essence of WEIBUILD’s efforts to digitize processes, standardize construction practices, and enable collective evolution is to transplant the procedures and standards from factories into the construction sector. This will inevitably cause significant disruption to the existing organizational methods within the construction industry, a transformation fraught with challenges that are both bitter and sweet.

Liang Yanxue deeply understands that transforming a traditional industry is extremely difficult. As a startup, WEIBUILD must refine its products to excellence, achieving orders-of-magnitude efficiency improvements at certain points, to gain acceptance within the industry. For instance, even if the plastering robot is three times more efficient than manual labor, the industry might lack the incentive to change its processes. But what if the efficiency improvement reaches 8 to 10 times? Then there may be industry players willing to give it a try, perhaps even compromising on their processes.

The first commercial deployment of WEIBUILD’s plastering robots was for the construction of the new campus of Jiaoda (Shanghai Jiao Tong University) Medical School. The success of this project paved the way for subsequent projects such as those with Kingold Real Estate and oral hospitals.

WEIBUILD plastering robot in operation during construction work.

In October 2023, WEIBUILD formed a joint venture with China Construction Eighth Engineering Bureau, aptly named "China Construction Future Intelligent Manufacturing."

Liang Yanxue revealed that, besides the plastering robots, WEIBUILD also has multiple product lines including rebar processing robots, putty coating robots, spraying robots, and measurement robots, all of which have entered the site testing phase.

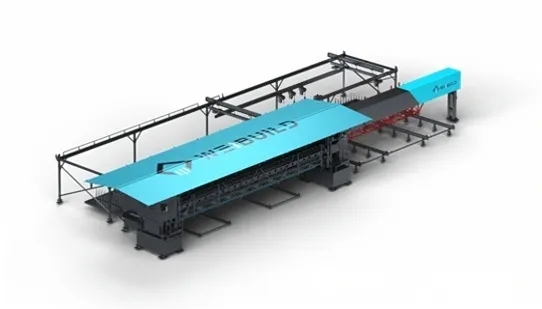

The products developed by WEIBUILD Technology

Market Implementation

"A picture that stays on the wall for three days becomes part of the background," Liang Yanxue observed. He believes that true disruptors in traditional industries must come from outside.

Liang Yanxue holds that robots are destined to replace human actions or a series of movements. In the context of the construction industry, this means identifying which actions have higher technical difficulty, greater labor intensity, and higher labor costs—these are the areas where robots can make the most significant impact by replacing human labor.

Another flagship product of WEIBUILD is the "rebar processing robot."

In the construction sector, there exists a unique phenomenon of distinguishing between junior workers (小工) and senior craftsmen (大工). Senior craftsmen possess specialized skills, while junior workers are often limited to material handling, leading to substantial costs incurred from inefficient transportation, especially evident in rebar processing. Raw materials must undergo several steps after entering the construction site, such as straightening, bending, cutting, and then proceed to longitudinal, vertical, and coiled reinforcement processes during construction. Traditional manual processing operations like cutting have also resulted in significant waste of raw materials.

Through WEIBUILD’s "fully automatic flexible rebar processing line," unmanned operations can be achieved, significantly reducing raw material wastage and operational costs. Amidst the current downturn in real estate, Liang Yanxue has keenly sensed the determination within the construction industry to adopt refined management practices and improve efficiency. This, in turn, has increased the industry's acceptance of intelligent construction systems represented by construction robots.

WEIBUILD INTELLIGENT REBAR MACHINING SYSTEM

Liang Yanxue also noted that as the cost-effectiveness and efficiency improvements brought about by construction robots become increasingly apparent, WEIBUILD has received more invitations to expand overseas.

Unlike the domestic market, the cost of construction workers abroad is much higher than in China. For example, in Singapore, labor costs are 5-8 times those of the Chinese market, and in the Middle East, they are 4-5 times higher. Currently, 90% of construction labor in the Middle East consists of imported workforce. Liang Yanxue believes that given the persistently high labor costs and shortages in the global construction industry, the optimal application scenarios for construction robot technology are beginning to emerge.

Facing a trillion-dollar construction market, Liang Yanxue feels that WEIBUILD still has much to offer. The company aims to "continuously deepen connections with all parties in the industrial chain, jointly building a new ecosystem for intelligent construction."