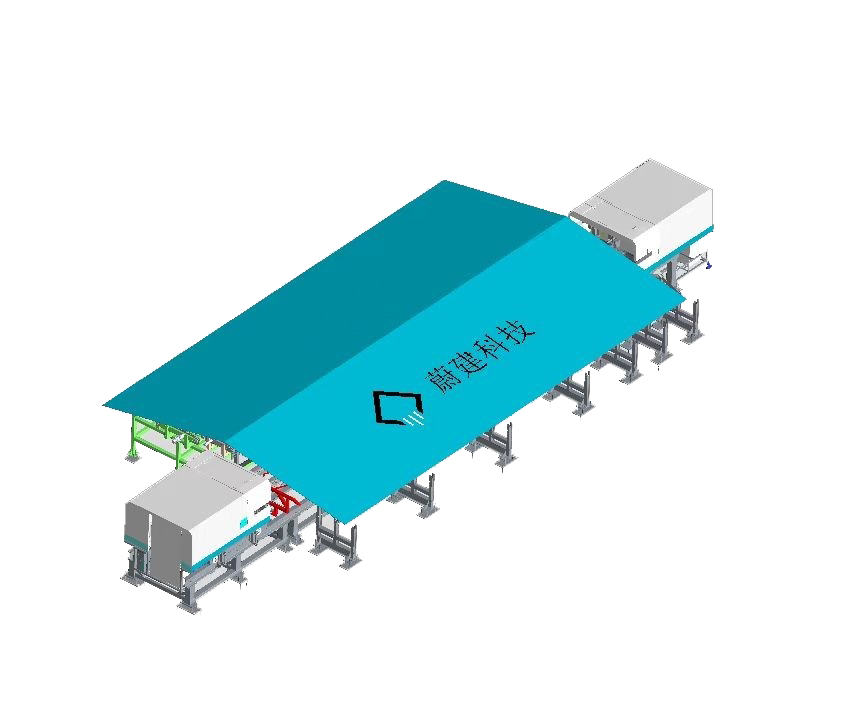

The system realizes intelligent production of rebar on-site (centralized processing plant). And through artificial intelligence blanking optimization, the scrap rate of reinforcing bar is greatly reduced.

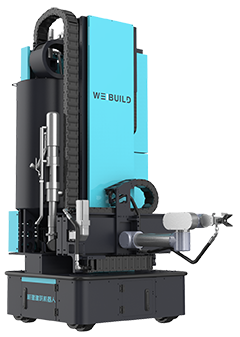

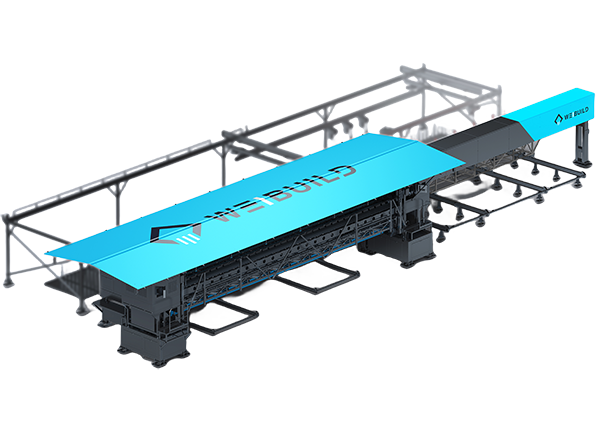

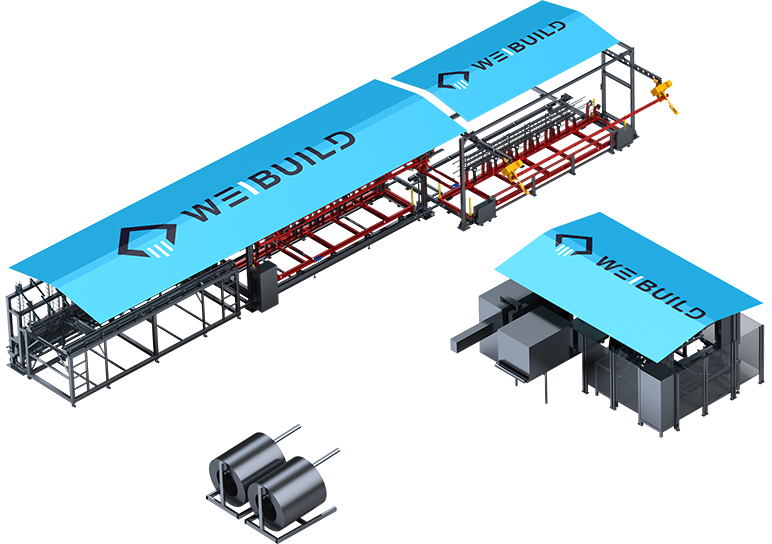

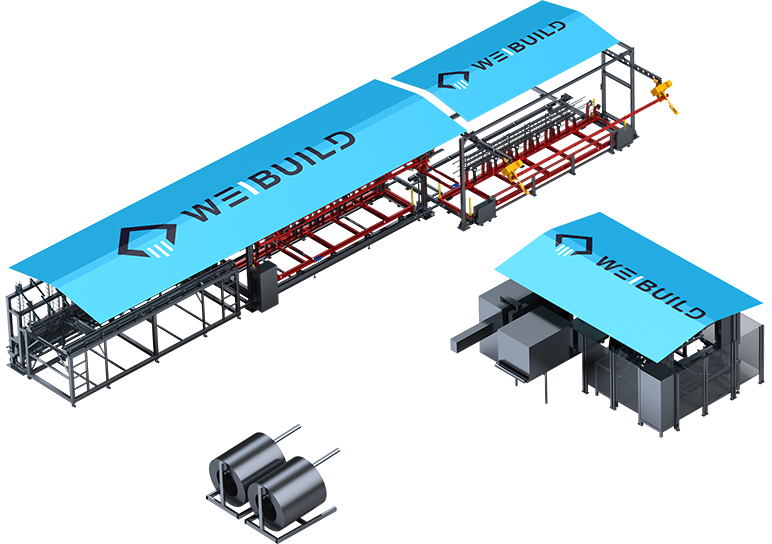

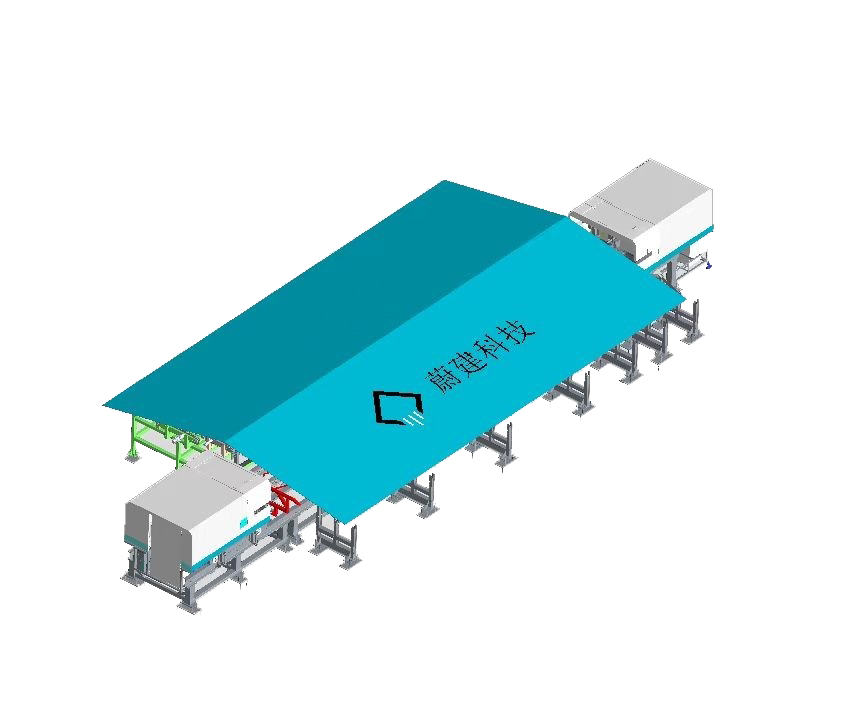

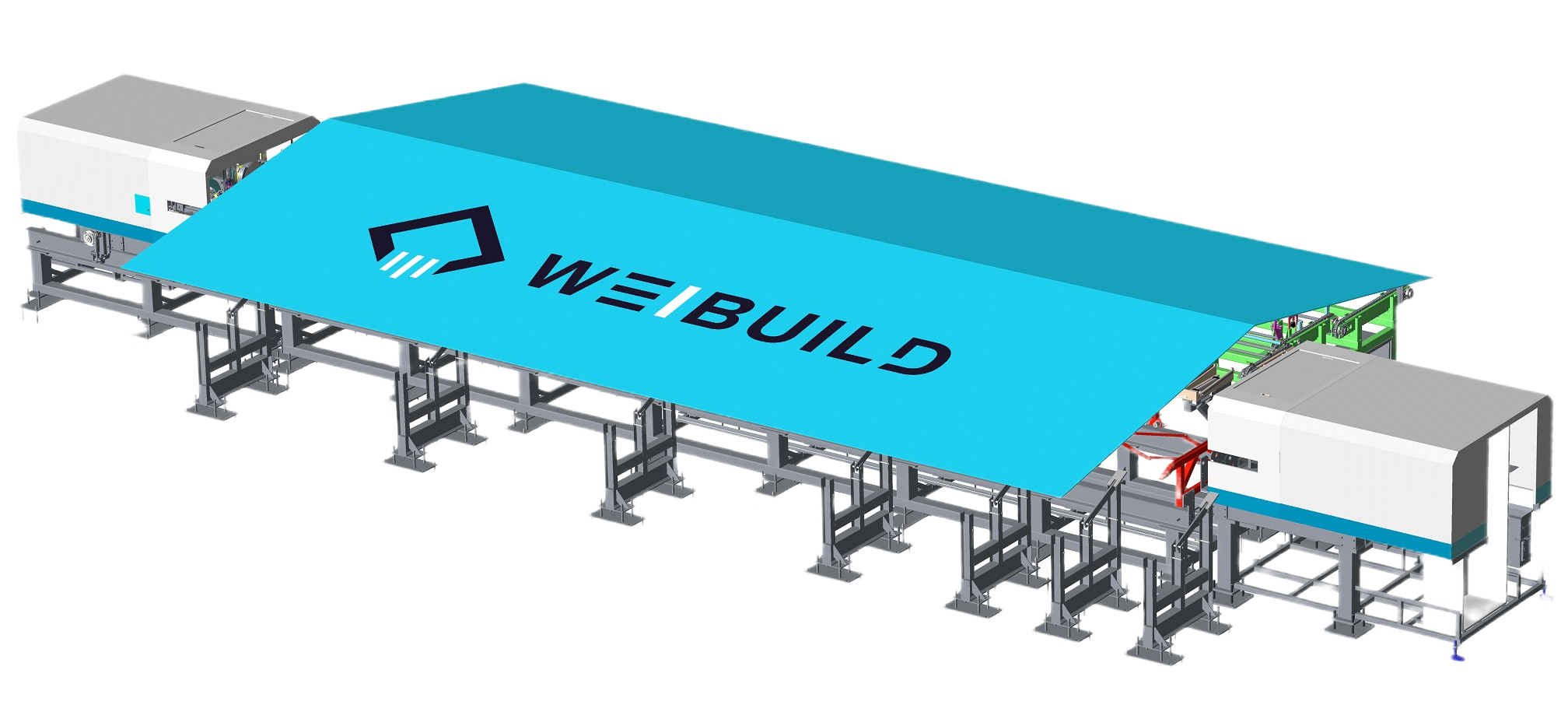

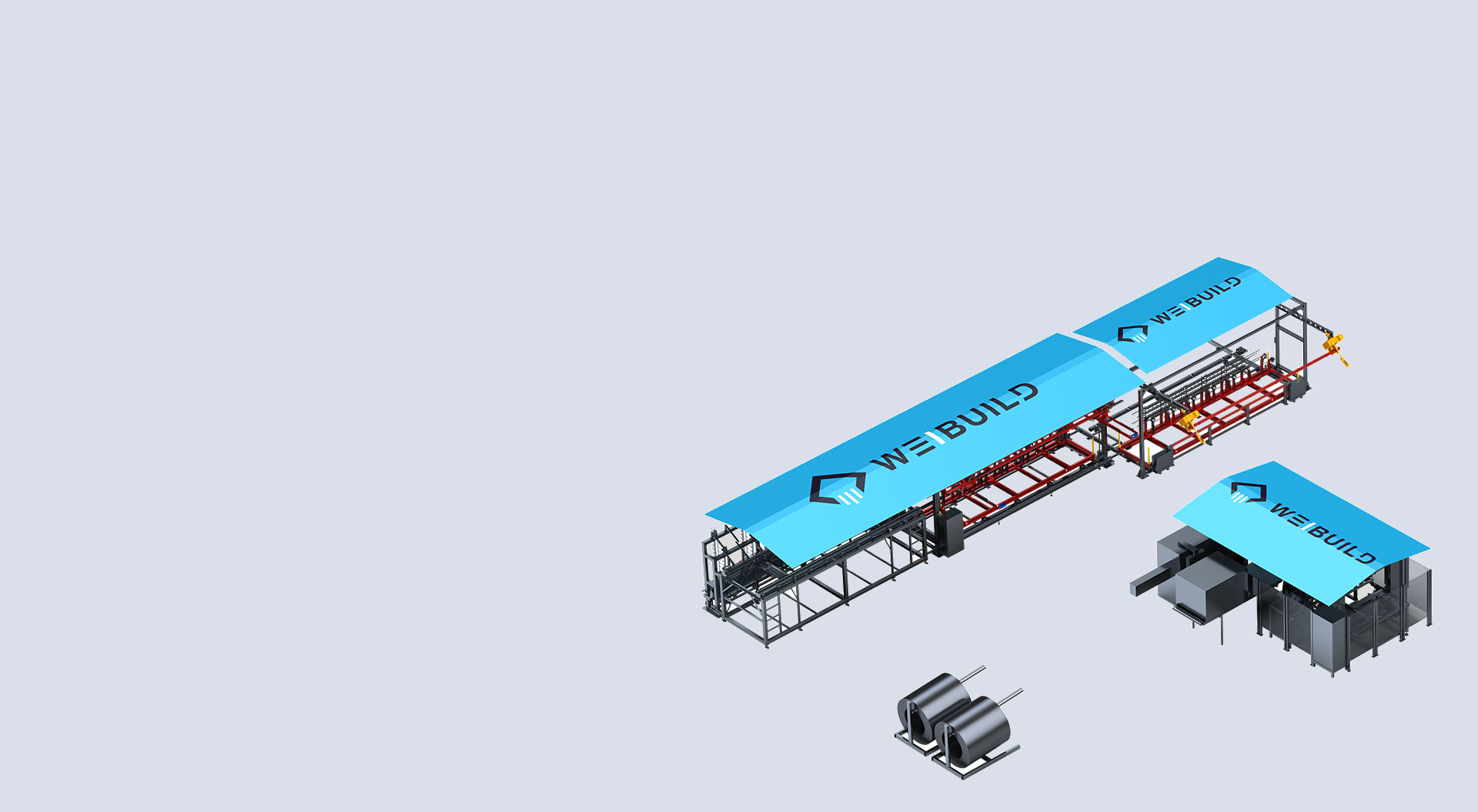

It is the world's first fully automatic ribbing and screwing unit, bending center, ribbing and screwing/bending automatic die changing, realizing automatic pick-up, transfer, fixed-size sawing, tapping and bending of rebar, sorting and packing of shaped rebar by component.Moreover, it is a flexible automatic production line, average capacity≥3.5t/h.

Functional Characteristics

Straight rebar, one time to complete fixed length cutting, tapping, bending operations.

Interactive finished goods silo with finished goods sorted by component.

Manual auxiliary raw materials into the warehouse, finished products, the whole unmanned automatic operation.

Visual image splicing and deep learning complete the unmanned picking of long bar.

Adaptive ribbing and rolling center can automatically complete reverse and reverse ribbing and rolling of different diameters.

The visual positioning realizes the automatic mold change of the bending center.

PLC main control unit can be connected to MES system operation.

Flexible automatic production line, average capacity ≥3.5t/h.

Container quick disassembly modular design.

Main Process Flow

Incoming materials are lifted to fixed silo → grabbing/cutting (mobile grabbing and cutting unit) → automatic rolling (adaptive ribbing and rolling unit) → bending (automatic mold change intelligent bending center) → unloading and packing by component

Processing Range

∅12-∅32, Length ≤12m