Expat PhD Turns into 'Construction Contractor', Develops Robotic Masons, Wins Orders from Middle Eastern Tycoons

On January 20, a grand residential building was under construction at Dubai Marina, part of a 122-story luxury project by the Six Senses Hotel. Upon completion, it will surpass the 472-meter Central Park Tower in New York to become the world's tallest residential skyscraper.

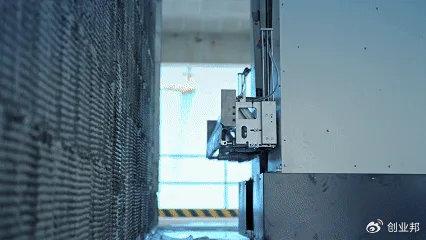

At the site, robots from Chinese startup WEIBUILD Technology were methodically applying mortar to walls. The day marked the first product inspection for WEIBUILD, and in a high-stakes test, a plastering robot completed 26 square meters of work in just 24 minutes—equivalent to a skilled laborer's half-day output. Inspectors confirmed the walls met or exceeded industry standards for flatness, verticality, and mortar consistency.

The successful inspection in the UAE marked a milestone for WEIBUILD, signaling its robots had achieved top-tier standards for Middle Eastern markets. In the critical plastering segment, WEIBUILD's robots now lead the field. Despite over 850 Chinese companies in the construction robotics sector, WEIBUILD—staffed by just over 100 employees—is the only firm to have successfully commercialized plastering robots.

"Many industries can be reinvented with existing technology, and construction is one of them," said WEIBUILD's founder and CEO, Yanxue Liang, a former researcher at Japan's FANUC, a global robotics giant.

Targeting High-Cost Construction Tasks with "Productive" Robots

Born in Shandong, Liang earned degrees from Shanghai Jiao Tong University's School of Mechanical Engineering before completing his doctorate at Tokyo Institute of Technology in 2006. He joined FANUC, one of the "Big Four" robotics firms, where he became a chief researcher in just 4.5 years. Witnessing Japan's industrial robot sector mature, Liang saw China's booming robotics potential and returned home.

After working on indigenous equipment development at Ningde Times, Liang left in 2018 to join Bright Dream Robotics, a Country Garden-backed construction robotics pioneer. A year later, he struck out on his own, inspired by venture capitalist Songyan Huang of Linear Capital, who identified force-controlled robotics as a transformative frontier.

"Population aging demands automation to fill labor gaps and boost efficiency in construction—a blue ocean market," Liang said. ABB data shows only 55% of global construction firms use robotics, far below 84% in automotive or 79% in manufacturing.

In 2020, Liang founded WEIBUILD in Shanghai's Baoshan district, focusing on two core tasks: interior wall plastering and steel reinforcement processing.

700㎡ in a Day: 14x Human Efficiency

Construction's fragmented standards posed challenges. "The industry lacks clear protocols—planning workflows is like navigating a maze," Liang said.

Plastering standards demand vertical and horizontal deviations within ±4mm over a 4-square-meter area and a bond strength of 0.2 megapascals. WEIBUILD's breakthrough came from digitizing master craftsmen's expertise. Engineers embedded with construction crews translated decades of hands-on knowledge into algorithms, discovering robots needed ~30kg pressure for optimal results.

WEIBUILD's Robotic Masons Achieve 700m² Daily, 14x Human Efficiency

The construction industry, despite its vast market potential, has long been an "automation laggard." As WEIBUILD Technology's CEO Yanxue Liang explains, "We're tackling a deeply traditional sector with unclear workflow rules and standards, making it challenging to optimize processes through parameters."

Precision Standards: Bridging the Gap Between Craftsmanship and Automation

In construction plastering, industry standards demand vertical and horizontal deviations within ±4mm over a 4m² area equivalent to the thickness of two 1-yuan coins—and a bond strength of 0.2 megapascals. Yet critical questions linger: What mortar-to-cement ratio? How much pressure should robots apply? At what speed? "There were no industry answers," Liang admits.

From Concept to Reality: A Relentless Pursuit

In May 2021, WEIBUILD secured millions in angel funding led by Linear Capital—despite having no robot prototypes. "The market either bets on WEIBUILD or waits a decade for alternatives," said Linear's Songyan Huang, who persisted despite internal skepticism.

For Liang, the journey recalled a career-defining moment: A FANUC executive once told him, "What you studied in the past doesn’t matter. What you do next defines your future. Don’t let a few years of study limit 30 years of potential." Liang internalized this: "Believe in your potential. With focus and effort, nothing is impossible."

Cracking the Craftsmanship Code

Master plasterers held the secrets to precision, but their tacit knowledge was hard to quantify. WEIBUILD sent PhD engineers to work side-by-side with veteran craftsmen, digitizing their expertise into algorithms.

Even the team's CTO, Jiazhen Mao—a polished overseas PhD—transformed into a fieldwork expert, his academic demeanor replaced by a weathered, sunburned appearance. Founders pushed wheelbarrows, unrecognizable to investors like Huang.

The Breakthrough: 30kg of Precision

After relentless trials, the team discovered a core insight: 30kg of pressure during plastering was critical to meeting standards. The result? A robotic system that digitized the process, delivering:

300-400m²/day per robot (peaking at 700m²/day—14x human efficiency)

0.08% void rate (vs. 0.7-1.2% for manual work)

Liang estimates one robot equals ten workers, with ROI achieved in ~12 months.

Beyond Plastering: A Full Construction Tech Stack

WEIBUILD's spraying robots now coat 100m²/hour with putty and 200m²/hour with latex paint, covering 90% of residential spaces. Its steel reinforcement lines boost productivity 6x while cutting labor costs by 80%.

Landmark Projects and Partnerships

The robots have completed 4 million m² across major projects:

Lingang New Area's 105 Community Financial East 9 Project (with China Construction Eighth Bureau)

Wuxi Liangxi Medical & Wellness Center (Shanghai Construction Group)

Suzhou Dushu Lake Hospital (China Construction First Bureau)

Teams are now 40% smaller than traditional crews, slashing management burdens. Clients include China's top firms: China Construction, China Communications Construction, CRRC, Poly Real Estate, and more.

A New Era for Construction Automation

As WEIBUILD scales, Liang emphasizes the industry's steep learning curve: "Operators need specialized training, and clients must adapt workflows for robots. But once adopted, automation becomes a moat."

With $100M+ in funding and global expansion underway, WEIBUILD is proving that even the most entrenched industries can be reinvented—one robotic brick at a time.

Global Expansion and Market Education

WEIBUILD's robots have completed 4 million sqm across projects like Shanghai's Lingang Financial District and Suzhou's Dushu Lake Hospital. Clients include China Construction, China Railway, and Poly Real Estate.

Yet challenges remain. "Operators need specialized training," Liang said, as traditional workers lack robotics skills. WEIBUILD trains agents and laborers to meet strict productivity benchmarks.

Market education is equally critical. "Construction projects require process adjustments for robots—a cultural shift," Liang noted. After years of persuasion, clients now adapt workflows to leverage automation.

From Dubai to Global Markets

With 100M+ infundingacrossfiverounds—including10M+ in Series A+—WEIBUILD has expanded to Shenzhen, Xiongan, and overseas. In 2024, robots debuted in Taiwan and Singapore, with UAE orders secured in January 2025.

"Overseas markets offer standardized conditions where robots thrive," Liang said, predicting major export breakthroughs within months.

"This isn't just a robot company—it's redefining construction," Huang said, praising WEIBUILD's fusion of robotics expertise and construction knowhow.

As Middle Eastern skyscrapers rise via Chinese robotics, WEIBUILD's vision of "robots doing what humans can't" is cementing its place at the forefront of the global construction revolution.